From shining skyscrapers to contemporary co-ops, from luxurious villas to swanky offices, glass has become a staple element in architecture and design projects. After all, not only does glass render a sleek and sophisticated charm to a space, but it is also designed to be highly functional. Fulfilling modern consumers’ modern and varied requirements, glass solutions are the top-pick in the current day and age. From matters of safety and durability to those of acoustic insulation or energy-efficiency, glass has something to offer. And all this while exuding a beauty that is ethereal, if there indeed is a word to describe the beauty of glass. And the precursor to all modern-day glass solutions is float glass.

What Is Float Glass?

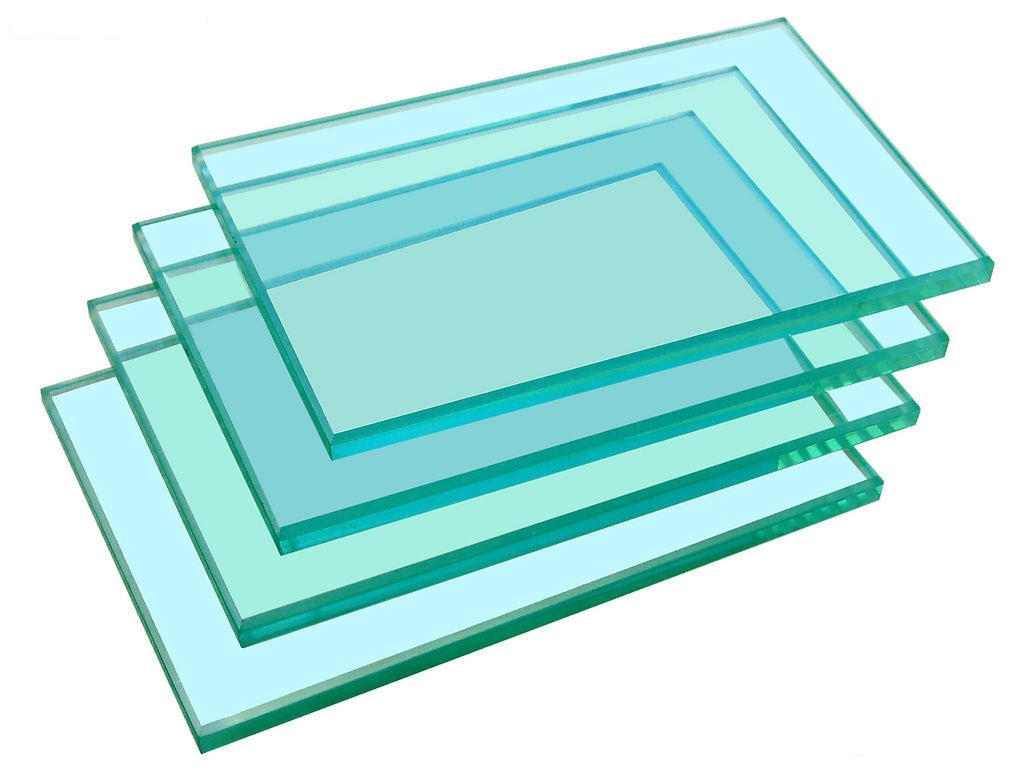

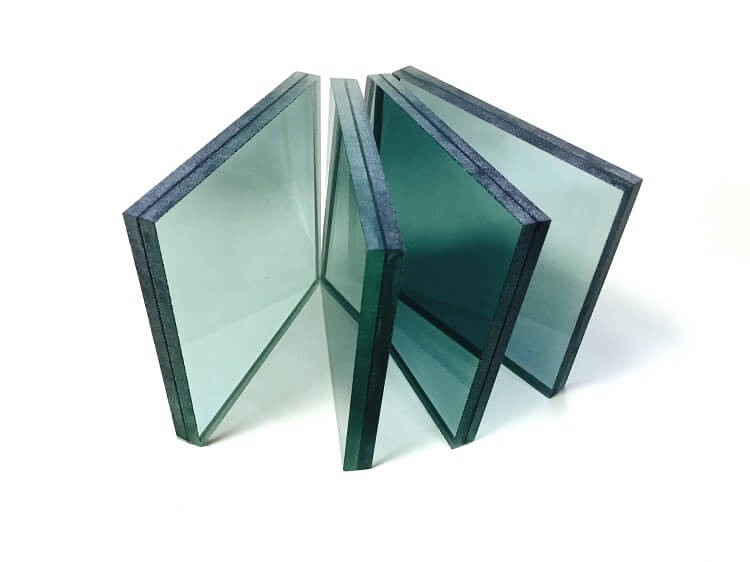

Float glass is essentially a super smooth, distortion-free glass that is used for designing other glass items such as laminated glass, heat-toughened glass, and so on. With a natural greenish hue and translucent nature, it is capable of transmitting about 87% of the incident light, and unlike sheet glass, float glass provides users with a crystal-clear view. Float glass owes its unique name to the process by which it is manufactured, wherein the molten glass is introduced into a bath of molten tin, causing the glass to float freely.

History of Float Glass

Float glass is the original piece of glass, the progenitor of an endless generation of glass solutions. And so, before we learn about how it is made, it is vital to know the real history behind it. With its invention dating back to at least 3600 years, glass has been a timeless material that has served many generations. But it wasn’t until the late 19th century that float glass came into existence. In earlier centuries, glass was made through the blowing and disc method. Since glass was simply used for creating windows in the old days, glass for window or other flat glass was produced from large discs of crown glass or by blowing glass bottles. The discs were usually cut into pieces, flattened together, and cut out to create the windowpanes from the large surface.

But somewhere between 1953 and 1957, Sir Alastair Pilkington revealed the idea of manufacturing float glass to the world. Although Henry Bessemer – a UK engineer, patented the earliest advances in automated glass manufacturing, it was Sir Pilkington who perfected the production of float glass. While the original process of producing float glass by Bessemer used a continuous ribbon of flat glass by forming the ribbon between rollers, the Pilkington method developed the ribbon of float glass using a molten tin in which molten glass would flow unhindered under the influence of gravity. Bessemer’s version was an expensive process, but with the efficiency of the Pilkington method, Sir Alastair was able to achieve profitable full-scale sales of float glass by 1960.

Process of Manufacturing Float Glass

As the most widely used form of glass in today’s world, it is essential to know about the manufacturing process of float glass. It all starts with a mixture of raw materials like sand, limestone, dolomite, soda, and salt cake. Next, these materials are melted in a furnace until they fuse together to form molten glass. To manufacture float glass, molten glass from a furnace is poured into a chamber containing a bed of molten tin. The tin tub is approximately 4 to 8 metres wide and up to 60 metres long. During the manufacturing process, the atmosphere inside the chamber is carefully controlled to ensure that float glass is manufactured correctly. The reason for using tin is that it is the only metal that remains stable in its liquid state at a high temperature of 600 degrees Celsius. The glass floating on the tin eventually takes the shape of the container and spreads from 90 to 140 inches wide with a varying thickness, which is determined during the time of manufacture.

Once the glass takes its proper shape, it is polished with fire. It is important to remember that only the upper surface, which is also known as the airside or score side, is fire-polished and the lower surface i.e., the tin side, is set to cool. For the cooling process, the glass is moved from the chamber to a temperature-controlled oven called a lehr. In this kiln, the glass is cooled slowly at a specific rate, which is known as annealing. Through the process of annealing, the glass is relieved of all internal stresses to create a sturdy, uniform, and smooth sheet of float glass. Establishing the right rate of cooling is a crucial step in the manufacturing process, as the wrong temperature can result in the formation of air bubbles and internal stresses. Once the glass is removed from the lehr, it emerges as a continuous ribbon at room temperature, which is flat, has a fire-finished topcoat, and possesses smooth, parallel surfaces. The glass is then finished to perfection with automatic cutters that trim edges and cut the glass to the desired length. It can have a thickness range of anywhere between 0.4 mm to 25 mm, depending on the requirements.

Benefits of Installing Float Glass

Now that we’ve seen the extraordinary process of manufacturing float glass, let’s take a look at some of the many benefits that float glass has to offer.

Durability

As we saw earlier, float glass is treated and cured in an oven to gain strength and durability. Despite it being more substantial than plate glass, it has the same amount of thickness, thereby revealing its incredible density and making it the superior glass for designing your space’s interior and exteriors.

Environment-Friendly

Energy-efficiency refers to the ability of glass to regulate indoor temperature by keeping interiors relatively cool during summers and warm during winters. You can also design a low-E glass from float glass by coating it with metal oxides. At AIS Glass, we possess high-performance, energy-efficient glass to reduce energy bills for your home and offices and conserve the environment. Our AIS Clear Float

Glass is also 100% recyclable and non-toxic to ensure that you do not leave behind a carbon footprint. It is also designed to be copper and lead-free for environmental preservation.

Multitude of Options

As the originator of all glass products, float glass can be diversified to create a wide variety of glass products. It can be designed with varying thicknesses, shades, and sizes to suit a myriad of architectural and consumer requirements. Several processing techniques, such as insulating, glazing, laminating, thermal toughening, silk-screen printing, sandblasting, bending, acid-etching, and many more, can easily be carried out on the AIS Clear Float Glass to achieve the desired look.

Applications of Float Glass

From domestic housing to commercial uses, float glass is a versatile item that serves many purposes. Now that we know about the many benefits of installing float glass, let’s take a look at some of the creative ways you can use float glass in your residential and commercial spaces.

Displays

Owing to its crystal-clear transparency, float glass serves as the ideal choice for displaying items. They can be used for showroom display cases, retail shop windows, and countertops to protect valuable items such as expensive watches, jewellery, and so on, yet be able to showcase the beauty of the unique products effortlessly. The AIS Clear Float Glass offers a sparkling and brilliant lustre with a crystal-clear finish to enhance the aesthetic appeal of your spaces with its luminosity.

Facades

There is nothing more affluent and sophisticated than the sight of towering and glistening skyscrapers made from glass and what better choice than float glass processed with glazing to create the perfect structure, which is just as aesthetic as it is functional? The glazing makes the glass tougher and increases its efficiency, whereas the float glass itself serves unparalleled charm and aesthetics with its superior clarity.

Wall Panels

Whether it is for creating partitions in your home or your personal cabin in the office. Wall panels are a great way to spruce up décor and increase the visual appeal of your spaces. Wall panels with tinted float glass can add a much-needed splash of colour to your space and breathe new life into the room. At AIS Glass, we indigenously manufacture only international-quality tinted float glass with heat-reflective properties using superior CVD technology. Depending on your preference, we offer customisable options for tinted float glass, such as lacquered and frosted glass, to help you create fun, vibrant spaces.

And there you have it – the complete story of float glass. Easily the most versatile glass of them all, using float glass for décor is a must when decorating your homes and offices. As India’s leading integrated glass manufacturer, our goal is to transcend the ordinary and create luxurious spaces. Hence,

we offer expert guidance to all our clients right from the initial selection process up until the final installation to help them create the ideal, picture-perfect space. Get your expert consultation today!